LSR self-regulating heating cables provide the most versatility in heat trace designs and applications.

This product has been used for over 1000,000 meters in our company’s key partners, PetroChina, CNOOC,Sinopec,China Aerospace,Wanhua Chemical and other global Fortune 500 companies.

Brand:

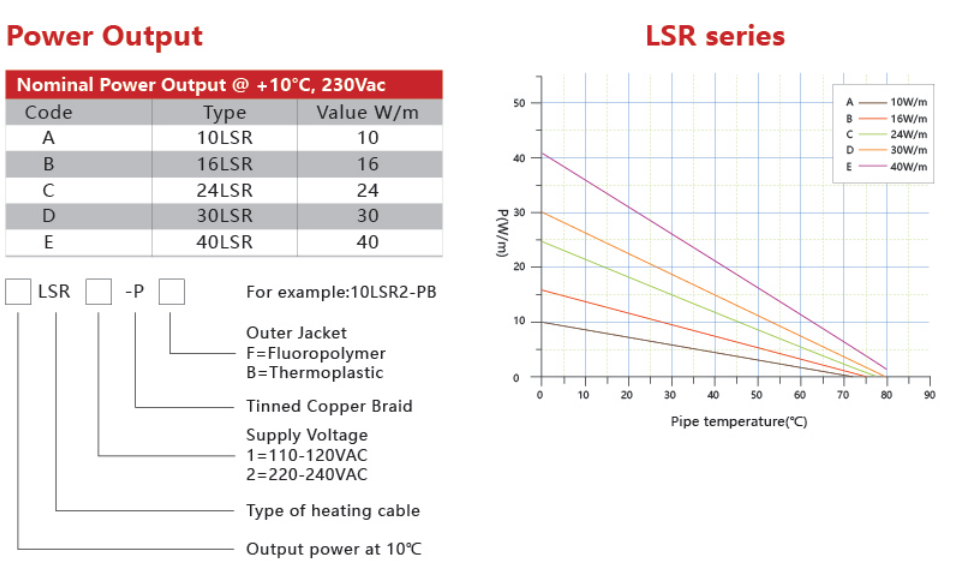

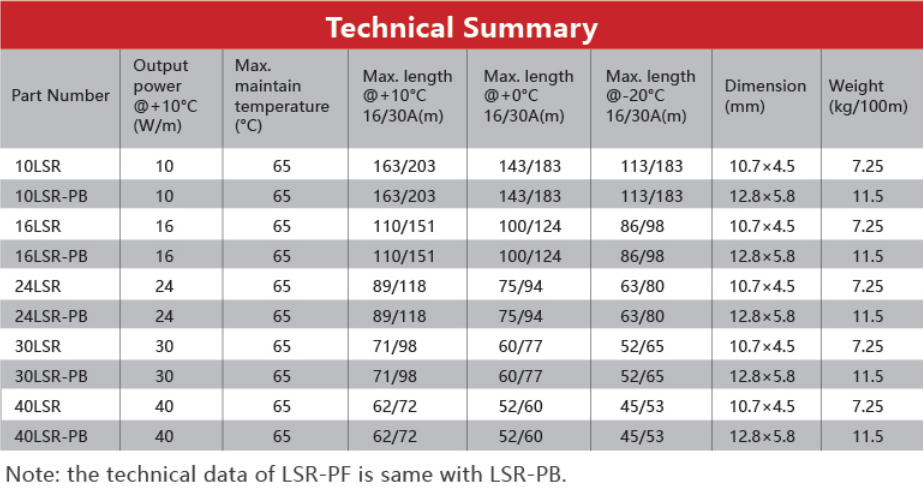

HuanruiPower Ouput:

10,16,24,30,40(W/M)Max. Maintain Temperature:

65℃Max. Exposure Temperature:

85℃Min. Installation Temperature:

-60℃Rated Voltage:

110V-120V/220V-240VMax. Resistance of Braid:

≤18.2Ω/KmBus Wire Gauge:

1.37mm²Certifications:

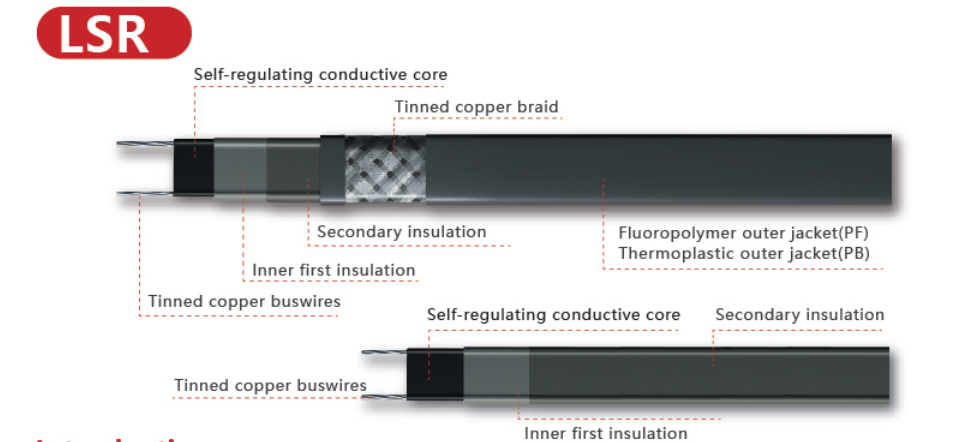

CE,EAC,EACEX,ATEX,IEx e IIC T6 Gb X,Ex tb IIIC T85°C Db XConstructed of a semi-conductive heater matrix extruded between parallel bus wires, a self-regulating cable adjusts its output to independently respond to ambient temperatures all along its length. As temperature increases, the heater's resistance increases, which lowers the output wattage.

Conversely, as the temperature decreases, the resistance decreases and the cable produces more heat. So thermostat is not necessary in some applications. It will never overheat or burnout even when overlapped. The cable can also be cut to any length. As the result, we got an energy efficient heating cable.

LSR self-regulating heating cable is resistant to watery and inorganic chemicals and protected against abrasion and impact damage.

The unique advantages of Huanrui self-regulating heating cable:

1. Improve the temperature resistance level: The temperature resistance level of the PTC semiconductor irradiation heating matrix can reach 100-110°C as needed to improve operational safety.

2. Reduce the starting current: Huanrui adopts double-layer co-extrusion technology, the starting current in the normal power range reaches <0.3A/M, and the ratio of starting current to steady-state current is less than 3 times.

3. Advanced insulation material: The insulation material is 100% matched with the PTC semiconductor irradiation heating matrix. In addition, it has excellent weather resistance, high temperature resistance, and insulation resistance of >2000MΩ, making it safer and more reliable.

4. New process: Huanrui adopts multi-layer co-extrusion technology. The insulation layer and PTC semiconductor irradiation heating matrix are extruded at the same time and completed in one go. The heating matrix and insulation are seamlessly integrated and cannot be peeled off, completely eliminating moisture and water when immersed, impurities cannot harm the core tape. Improve product service life.

Never overheat or burnout when overlapped. Cut to any length. Easy to install.

LSR Series:

LSR: Flame retardant thermoplastic outer insulation jacket protects against certain inorganic chemical solutions, it also protects against abrasion and impact damage.

LSR-P: Tinned copper braid provides additional mechanical and ground protection.

LSR-PB: Flame retardant thermoplastic outer jacket protects against certain inorganic chemical solutions, it also protects against abrasion and impact damage.

LSR-PF: Fluoropolymer outer jacket is used for exposure to organic or corrosive working conditions.

LSR is ideally used for process temperature maintenance and frost protection of regular diameter pipelines, tanks, valves, flanges, roof & gutter de-icing, snow melting and other applications of low temperature working conditions. It is suitable for hazardous area, and cable with fluoropolymer outer jacket can also be used in hazardous area and corrosive area. The cable with UV stabilized thermoplastic elastomer outer jacket is provided to cover the braid for wet applications and exposure to the sun.